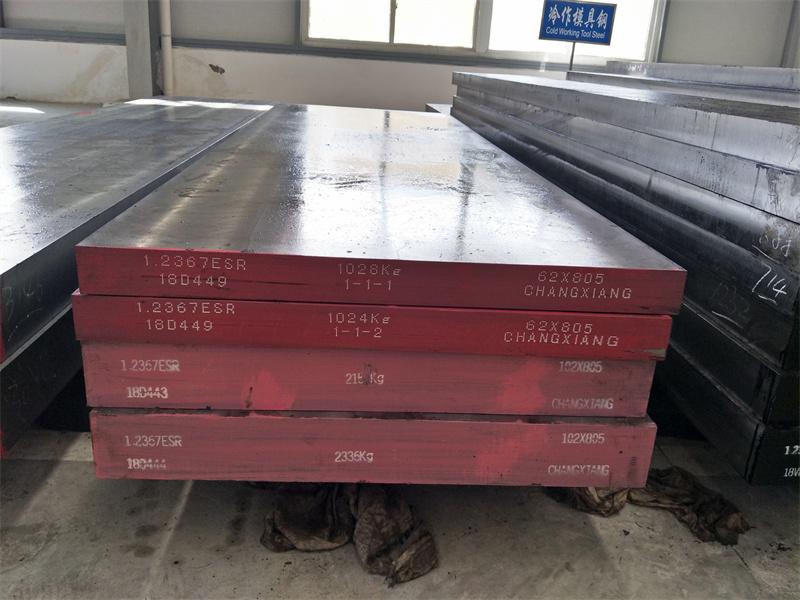

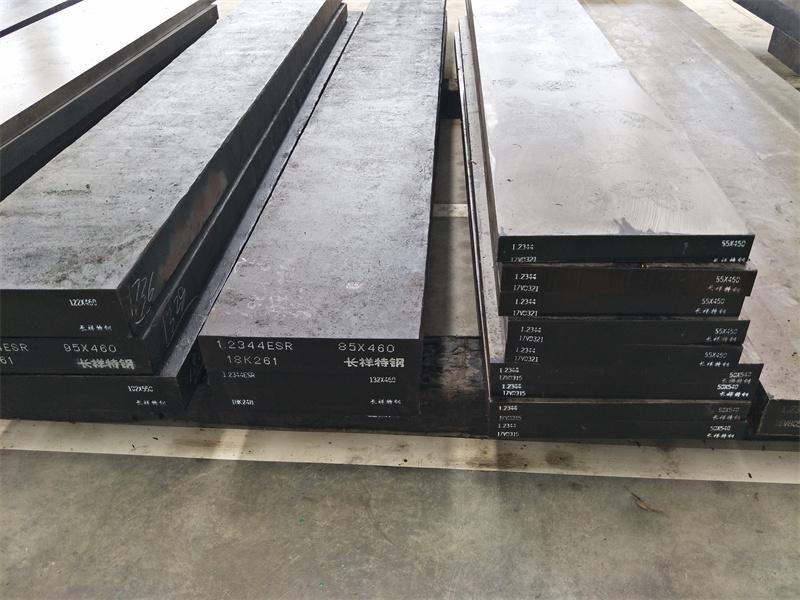

热作模具钢 热作模具钢对硬度要求适当,侧重于红硬性,导热性,耐磨性。因此含碳量低,合金元素以增加淬透性,提高耐磨性、红硬性为主。 热作模具的工作条件 热作模具钢 包括锤.

Call: 0086-13725760596

Email: xfz5018@twmetal.cn

产品特点

| 编号 NO: | 近似钢号 | 用途 | Application | ||||

| 中国GB | 美国AISI | 德国DIN | 日本JIS | 外企 Foreign Enterprise | |||

| 1 | 4Cr5MoSiV1 | H13 | 1.2344 | SKD61 | ASSAB 8407 | 铝压铸、挤压模、薄壁塑胶模 | For aluminum die casting,pressing mold.pladtic thin wall mold |

| 2 | 4Cr5MoSiV | H11 | 1.2343 | SKD6 | 铝压铸、挤压模、薄壁塑胶模 | For aluminum die casting,pressing mold,pladtic thin wall mold | |

| 3 | *4Cr5Mo2SiV | H13 Modify | 1.2367 | 铝、镁、钛压模、挤压模,性能明显优于H13 | For aluminum,agmesoi,titanium press mold,press-ing mold, pressing mold | ||

| 4 | *3Cr3Mo3V | H10 Modify | 1.2365 | SKD7 | 热稳定性高,铜挤压模 | For Cu press mold,better heating staability | |

| 5 | 3Cr2W8V | H21 | 1.2581 | SKD5 | 热稳定性高,冷热交变较缓的热作工具及锻模 | For hotwork tool and forging mold,good heating stability | |

| 6 | 4Cr5MoV1Si | H13 Modify | 1.2344 | ASSAB 8407 | 锤锻模块用钢,耐磨好 | For forging mold,good wear-resistin | |

| 7 | 5CrNiMo | L6 | 1.2713 | SKT4 | 大中型锤模块用钢 |

For mid-large size of forging mold |

|

| 编号 NO: | 热作模具钢化学成份(% ) Chemical composition |

退火状态 硬度≤ Annealed Hardness |

热处理温度(℃) Heal treatment temp |

回火硬度 HRC Secondary hardness | |||||||||||

| C | Si | Mn | P≤ | S≤ | Cr | W | Mo | V |

淬火 Hardening |

回火 Tempering | |||||

| 1 | 0.39 | 1.10 | 0.30 | 0.028 | 0.020 | 5.10 | 0.30 | 1.55 | 0.90 | 235 | 1020 | 530-560 | 54-27 | ||

| 2 | 0.39 | 1.10 | 0.30 | 0.028 | 0.020 | 5.10 | 0.30 | 1.35 | 0.40 | 235 | 1020 | 530-560 | 54-47 | ||

| 3 | 0.38 | 0.50 | 0.30 | 0.018 | 0.012 | 5.10 | 0.50 | 1.80 | 0.80 | 235 | 1020 | 530-560 | 52-53 | ||

| 4 | 0.32 | 0.35 | 0.30 | 0.028 | 0.020 | 3.00 | 2.80 | 0.55 | 235 | 1020 | 530-560 | 52-53 | |||

| 5 | 0.35 | 0.35 | 0.30 | 0.030 | 0.030 | 2.50 | 8.00 | 0.30 | 241 | 1100-1150 | 580 | 50 | |||

| 6 | 0.39 | 1.00 | 0.40 | 0.030 | 0.020 | 5.20 | 1.70 | 1.40 | 0.90 | 241 | 1100-1150 | 590-630 | 53-47 | ||

| 7 | 0.55 | 0.35 | 0.65 | 0.030 | 0.030 | 0.65 | 1.20 | $0.10 | 235 | 预硬840 | 预硬500 | 40-45 | |||

Standard |

JIS / ASTM / AISI / SAE / EN /DIN / BS / GB / API |

Grade |

SS400, S355JR, S355J0, S355J2 Q345A-Q345E, Q460C etc. |

Delivery Condition |

U / N / A / S / FP / AC / QT / EFS |

Shapes |

Round / Square / Flat / Hexagon |

E-mail:xfz5018@twmetal.cn